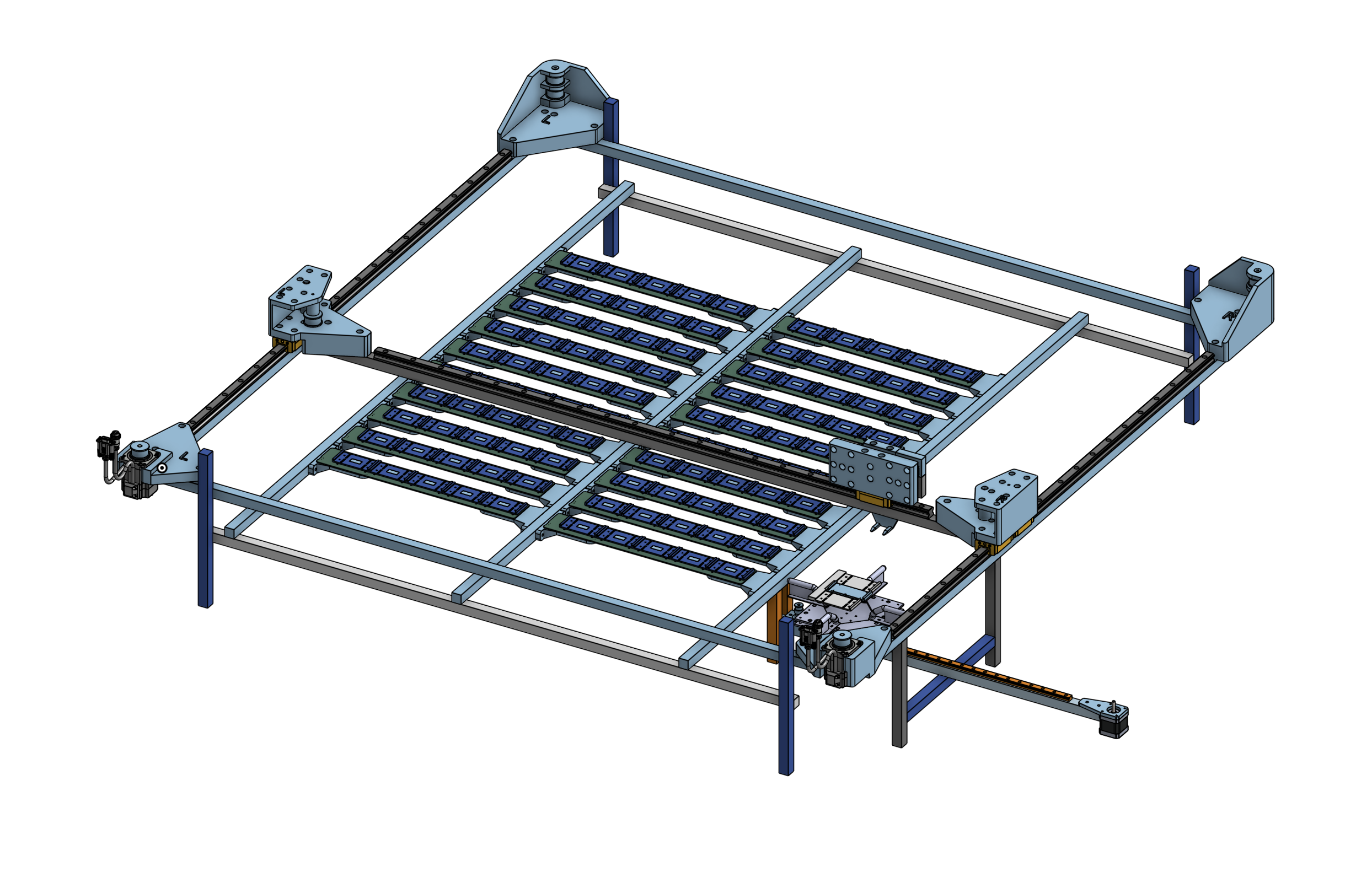

At Northwestern’s Center for Robotics and Biosystems, I’m developing a 1.5 m × 1.5 m CoreXY gantry system to autonomously manage a 150-drone battery-swap array. The project blends mechanical design, fabrication, and embedded systems, with over 100 custom parts created through 3D printing, laser cutting, and machining.

After completing a scaled down version of the final product, I redesigned the gantry’s architecture to dramatically cut unwanted torque and reduce racking from ~8° to less than 0.5°, while also integrating closed-loop stepper control and I²C networking for 20+ charging nodes. The result is a scalable platform that combines precision motion with robust distributed electronics.

This project is still in progress, which is why photos and final results are limited for now. Feel free to reach out to me directly for the latest updates.